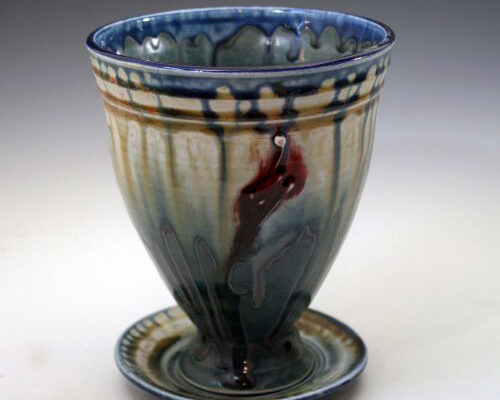

Celtic Pottery is comprised of Janet Gaddy and Tim Moran. The studio is a family owned enterprise based in Brown Summit, NC. Each piece they produce is hand thrown in fine porcelain and meticulously glazed via our 30 hour, 10-step process. Each of their designs features a unique zinc-based glaze, never to be repeated.

The Crystalline Process:

Gorgeous crystals are grown inside the glaze during a complicated firing schedule. The entire 10-step can take up to 30 hours on a single piece. Even with great care, the failure rate is high. Therefore only a few potters have accepted the challenges of crystalline pottery. Crystal glazes require an intricate, long cooling schedule. The zinc based glazes run off the pot and need special containers to collect the melted glaze so it does not ruin the kiln shelves. It is impossible to repeat the design on any piece; therefore each pot is unique. The crystals actually form in the glaze in a chemical reaction during the cooling process and grow from small nuclei created during the melting process when the silica and the zinc come together to form zinc-silicate. The crystal glazed ware is fired to approximately 2340 degrees F. and then held in the kiln for cooling between 2000 F. and 1830 F. for approximately 3-5 hours depending on the glaze. Each piece is created using high fire fine porcelain.